Tel:15324226647 Mob:+86-13930552202 Skype:Lengstech Whatsapp: +86-13930552202

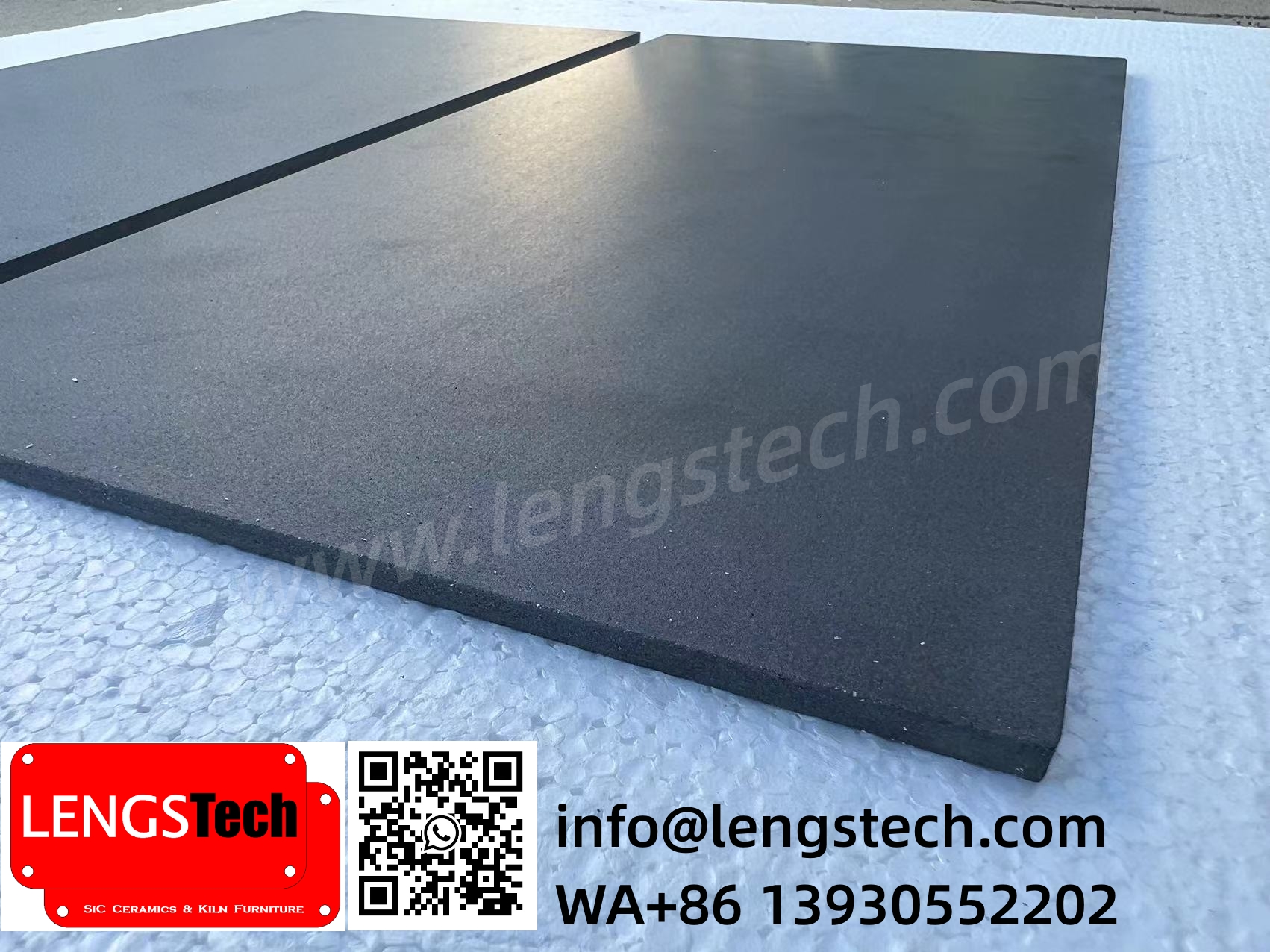

Silicon carbide (SiC) setter plates are critical high-temperature bearing and sintering components in semiconductor manufacturing. With excellent high-temperature resistance, chemical stability and structural reliability, they are essential consumables for core processes like sintering, annealing and epitaxy of semiconductor materials (e.g., silicon wafers, GaN, SiC power devices) and related parts. Below is an abridged analysis of their core application scenarios and outstanding advantages.

SiC setter plates are widely used in key links of the semiconductor industry chain, adapting to high-temperature, clean and high-precision process requirements:

Semiconductor Material Sintering & Annealing: Bear substrates (Si, SiC epitaxial wafers, GaN, ceramic substrates) in processes like densification sintering, stress-relief annealing and doping activation. Suitable for 1200℃–2400℃, compatible with vacuum, inert gas or reducing atmosphere.

Power Semiconductor Device Manufacturing: Provide uniform temperature field and stable bearing surface for eutectic soldering and sintering soldering of SiC/GaN devices. Meet the demand for large-size (8-inch/12-inch) and high-precision plates driven by new energy and photovoltaic industries.

Semiconductor Packaging Material Sintering: Ensure low thermal expansion coefficient in co-firing of LTCC/HTCC ceramic packages and metallization layers, preventing warping, cracking and contamination.

Epitaxial Growth Auxiliary: Serve as bearing substrates in CVD processes of silicon/SiC epitaxial wafers, ensuring uniform epitaxial layer thickness and excellent crystalline quality via high thermal conductivity and temperature uniformity.

Compared with alumina ceramics, graphite and mullite, SiC setter plates have irreplaceable advantages for semiconductor manufacturing:

Superior High-Temperature & Thermal Stability: Melting point up to 2700℃, long-term service temperature 1600–1800℃. Excellent thermal shock resistance (α≈4.5×10⁻⁶/℃), no cracking/deformation in rapid heating/cooling, service life up to thousands of cycles.

Chemical Inertness & High Cleanliness: No reaction with process gases, semiconductor materials or solders at high temperatures. High purity (SiC≥99.9%, impurities<10ppm), no volatile substances, meeting ultra-clean requirements.

High Hardness & Mechanical Strength: Mohs hardness 9.5, wear/scratch-resistant, surface flatness maintained at ±0.01mm/m after long-term use. Bending strength≥400MPa, suitable for large-size plates (e.g., 600×600mm), impact-resistant.

Uniform Thermal Conductivity: Thermal conductivity 120–150W/(m·K), ensuring surface temperature uniformity≤±2℃ (±1℃ for large-size plates), avoiding stress cracking from temperature gradients.

Low Thermal Expansion & Dimensional Stability: Thermal expansion coefficient matching Si/SiC, reducing thermal stress and deformation risk. Dimensional change rate<0.1% after long-term use, ensuring mass production consistency.

Corrosion Resistance & Multi-Atmosphere Compatibility: Resists acids, alkalis and molten metals, compatible with vacuum, inert and reducing atmospheres, with strong versatility.

Trends: Large-size (8-inch/12-inch compatible), functional customization (grooving, drilling, composite coatings) and lightweight designs.

Selection Indicators: Temperature compatibility (ordinary SiC≤1600℃, reaction-bonded SiC≤1800℃), dimensional accuracy, purity (impurities<5ppm for semiconductor grade) and atmosphere adaptability.

Summary: SiC setter plates are indispensable in semiconductor manufacturing, especially for third-generation semiconductors. With technological upgrading and cost optimization, their market demand will continue to grow rapidly.

Tel:15324226647

Mobile:+86-13930552202

E-mail: info@lengstech.com

Skype: Lengstech

Whatsapp: +86-13930552202

Copyright 2026 © Tangshan LENGS Technology Co., Ltd. All Rights Reserved.