Tel:15324226647 Mob:+86-13930552202 Skype:Lengstech Whatsapp: +86-13930552202

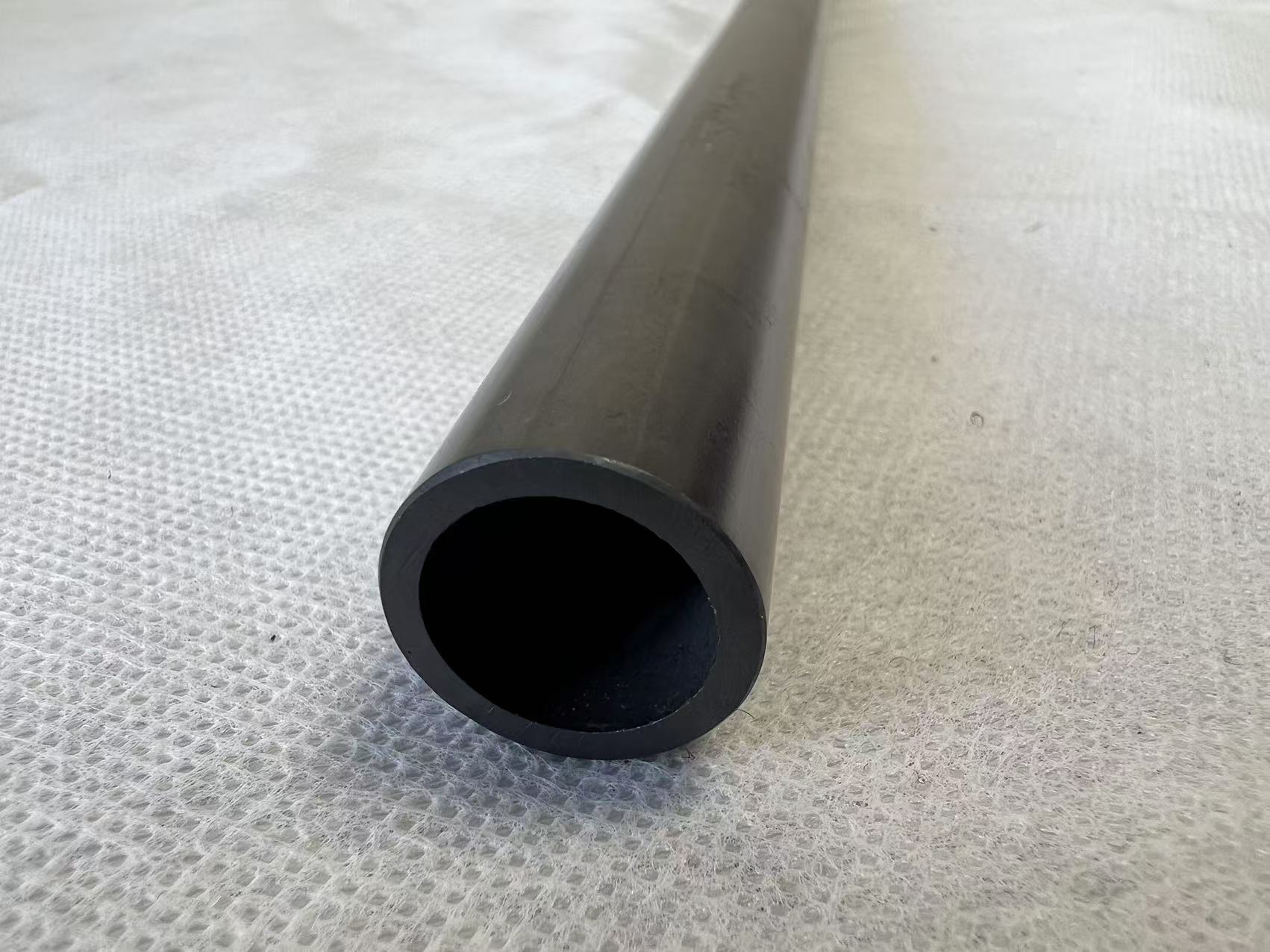

What are the advantages of pressureless sintered silicon carbide over reaction-bonded silicon carbide?

In terms of performance

- Good high-temperature performance: The mechanical properties and corrosion resistance of pressureless sintered silicon carbide ceramics at high temperatures are better than those of reaction-bonded silicon carbide. Their properties remain basically unchanged at 1600 °C. However, for reaction-bonded silicon carbide, due to the melting of free silicon above 1400 °C, its strength will decline rapidly.

- Strong corrosion resistance: Pressureless sintered silicon carbide has a relatively high purity with a mass fraction of SiC greater than 99%. Its corrosion resistance is much better than that of reaction-bonded silicon carbide. It can work stably in harsh chemical environments such as strong acids and alkalis. In contrast, the free silicon in reaction-bonded silicon carbide cannot resist the corrosion of alkaline substances and strong acids like hydrofluoric acid.

In terms of process

- Capable of preparing components with complex shapes and large sizes: Pressureless sintering can adopt various forming processes, such as dry pressing, isostatic pressing, slip casting, and extrusion molding. It can break through the limitations of product shape and size and is suitable for the mass production of ceramic parts with different shapes. It can be used to prepare silicon carbide ceramic parts with complex shapes and large sizes. However, reaction-bonded silicon carbide has higher requirements for shapes and it is more difficult to prepare silicon carbide materials with complex shapes.

- Good product quality: The pressureless sintering process is stable with good batch stability. With the action of appropriate additives, it can obtain relatively high strength and toughness. The product has a high density, which can reach above 3.17, close to the theoretical density of 3.22, and its products have smoother surfaces. Although the dimensional change of reaction-bonded silicon carbide during the densification process is relatively small, its bulk density is generally between 2.97 and 3.05.

Tel:15324226647

Mobile:+86-13930552202

E-mail: info@lengstech.com

Skype: Lengstech

Whatsapp: +86-13930552202

Copyright 2026 © Tangshan LENGS Technology Co., Ltd. All Rights Reserved.